Is Your Furler Trying to Tell You Something?

- Bill Wiggins

- Nov 7, 2025

- 3 min read

If you have been sailing for a while, chances are your boat’s furling system has been one of those “set it and forget it” pieces of gear. It quietly does its job season after season, rolling and unrolling your headsail without complaint. But if you are still sailing with an older Harken MKI, MKII - or MKIII furler, or similar systems from Schaefer, Hood, or Profurl - it may be time to take a closer look.

That shiny aluminum extrusion on the forestay might not seem like a ticking clock, but it is. If the furler is original to the boat, there is a very good chance the headstay inside is just as old. Stainless wire rigging has a limited lifespan, and the forestay is especially vulnerable because it lives its entire life hidden inside the furler. It is an enclosed, moisture-prone space where corrosion and metal fatigue can go unseen. Plus, getting parts for these older units is extremely difficult.

Most insurance companies now recommend- even or require standing rigging replacement every 10 to 15 years, depending on usage and environment. Beyond that window, your coverage and your mast could be at risk.

How to Tell What You Have?

Identifying your furler model is easier than you might think.

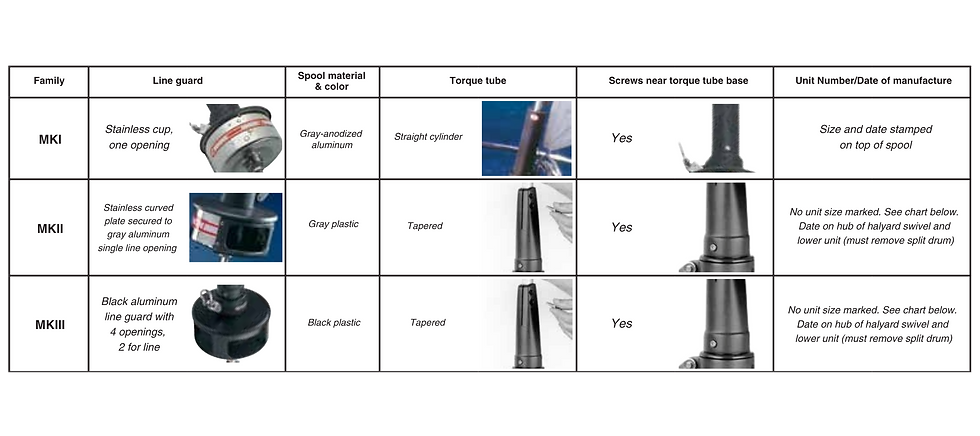

Harken’s MKI systems, built from the late 1980s through 1994, had brushed aluminum drums and exposed fasteners. The MKII followed with smoother contours and polished finishes. MKIII arrived in 2000 with anodized housings, recessed screws, and sleeker foil profiles.

Other popular systems tell their own stories. Early Schaefer units featured square edged drums with visible hardware, while newer models have enclosed drums and stainless feeder cages. Classic Hood Seafurl 700 and 800 units have perforated plates, whereas the SL series went fully enclosed. Profurl’s green anodized foils and black composite drums are the hallmark of their earlier designs, replaced today by sleek silver and black “C series” units.

If you are unsure which system you have, bring a few photos by your TPG service office or send them via email. We can usually identify the model within seconds, and that tells us a lot about its age.

Why It Is Worth Checking

When a furler or forestay fails, it rarely does so under calm skies. The loads generated by a flogging headsail can be tremendous, and a failed stay almost always means mast damage or worse. Replacing your headstay proactively is not just smart maintenance, it is peace of mind.

Modern furling systems are lighter, smoother, and easier to service than their predecessors. Bearings are sealed, friction is reduced, and drum designs have come a long way in keeping line feeds smooth, effortless and free of abrasion.

If your system is more than fifteen years old, it is time to plan an inspection. The process is straightforward. We measure the stay, inspect the wire or rod for corrosion, check the terminal fittings, and examine how the furler itself is running. If replacement is needed, it is an ideal time to upgrade both — new rigging, new furler, and a fresh start before launch.

Let's Have a Look!

If you are not sure how old your furler or headstay is, do not wait until it tells you the hard way. Contact your local TPG Marinas Service Department or reach out to Bill Wiggins directly at bwiggins@tpgmarinas.com or (860) 556-2000 ext. 2555 to schedule a quick inspection or discuss upgrade options.

Sometimes the best way to keep your sailing season smooth is to catch the little things before they become big ones.

About The Author

Bill Wiggins has been sailing for nearly fifty years and working professionally in the marine industry since the 1990s. A licensed 100 Ton Master Captain, lifelong sailor, and experienced rigger, Bill has worked with everything from coastal cruisers to high performance race boats. He currently serves as Service Operations Manager for TPG Marinas, helping owners maintain, refit, and modernize their vessels with safety and reliability in mind.

.

Comments